7 Tips to Reduce Construction Site Waste

Plan ahead

Planning to cut down construction site waste is very important. It helps the environment, saves money, and makes your project run more smoothly. If you start early and use smart steps like clear material estimates, good inventory control, and the right building methods, you can keep construction waste low. A strong construction waste management plan is key for your job. You can go for prefabricated parts or use modular construction so there is less need to cut and fix materials onsite. This also means you throw away less excess materials.

It is also important to keep clear communication with everyone involved in the project. This helps people stay on the same page and stops the problem of ordering too much. Working in ideas like sustainable design can help a lot. For example, try to use recycled or local building items and put a good recycling and sorting system in place to better handle construction waste. This builds up a plan that is more friendly to the earth.

Using new technology such as Building Information Modeling (BIM) helps you make better plans, see how things will fit, and use your stuff the best way possible. This cuts down on construction waste on your site. A strong waste management plan does not just lower the bad impact on the earth—it can give you a faster path to finish your build and save costs at the same time. When you manage construction waste in the right way,

Deconstruct before demolition

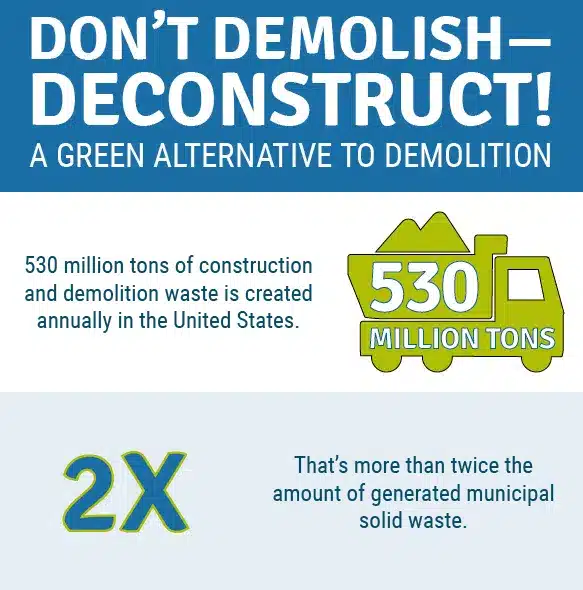

Deconstruction before starting demolition is a way to be more eco-friendly on any construction site. It helps cut down on site waste by taking buildings apart step by step on a number of levels. Workers can get usable materials like bricks, lumber, metals, and fixtures out of the old building. This means that people can use those things again instead of throwing them away. When you reuse what you take out, you help cut the need to use new materials and send less waste to a landfill.

Carefully deconstructing buildings lets their parts be reused or even sold. People can give these items away or use them for new projects. This practice is good for both the environment and the community. A link on this page shares more about how it works.

By using deconstruction before demolition, people can better spot and deal with hazardous materials. This means safer work for those on site and less harm for the environment. Handling disposal the right way means there is less chance for things to go wrong.

Choosing deconstruction in construction projects helps make the built environment better for everyone. It cuts the footprint left on nature, supports waste reduction, and shows us a good way to manage the world’s resources. By making this practice common, the construction industry can be more responsible and help keep our world better for those who come after us.

Try out new building methods

Today, it is important to think about sustainability and how our actions affect the environment. That is why many people in the building industry want to find new ways to cut down on construction waste at every construction site. Using new building methods brings a good chance to help with waste reduction in the industry. With methods like prefabrication, modular construction, and new building materials, builders can really cut back on the waste that comes from building work.

Prefabrication means that big parts of a building are made off the site in a factory with great care. By doing it this way, there is much less material wasted when putting everything together at the construction site.

Modular construction uses units that are the same size and shape. With these, people can build quicker and do not end up with as much excess materials or construction debris that might end up as waste.

A report by the World Green Building Council says that making building parts off-site can lower construction waste by up to 90%. It can also make projects finish about 50% faster than with older ways

Recycle and reuse

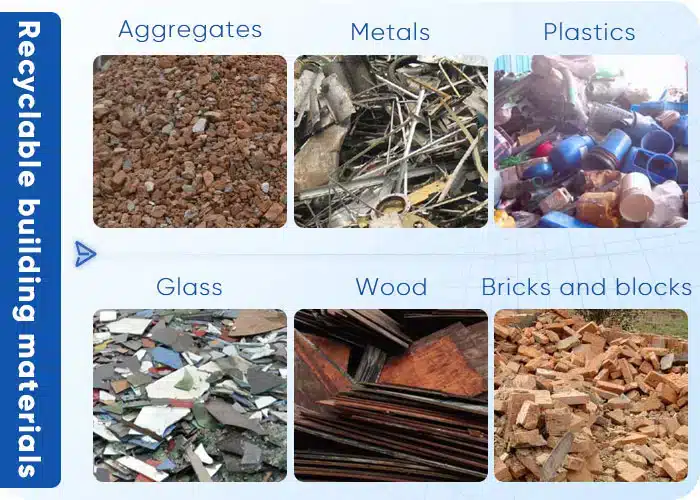

Recycling and reusing materials at construction sites are important for reducing waste and cutting down on the environmental impact. By implementing efficient recycling practices, materials like wood, metal, concrete, and plastics do not end up in landfills. Instead, these can be repurposed and used for future projects. For example, crushed concrete works well as aggregate for making roads or starting new construction projects. Reclaimed wood can be used again for things like furniture or adding detail to buildings.

You can also use recycled steel in your construction projects. This choice helps a lot because it takes less energy to make than new, or “virgin,” steel and leads to lower carbon emissions. Another helpful practice is using reusable materials such as formwork systems, scaffolding, and scrap wood. These not only help with waste management but also lower costs on your project.

When you choose to recycle, reuse, and bring these appliances and materials back into your construction projects, you practice sustainability and help lower your industry’s environmental impact. A circular way of working, where materials constantly move back into new projects, helps the environment and saves valuable resources. Teaming up with your suppliers to buy recycled materials, as well as making waste management plans for demolition or building

Order the right amount of materials

Ordering the right amount of materials like drywall is key to cutting down waste at a construction site. You need to look closely at what the project needs and how much of each thing will be used. When you estimate the right amount, there will not be as much excess material left over, which often just goes to waste. This also means you do not spend more money on extra stuff you do not use, and it helps the environment because there is less going in the trash.

Using technology such as Building Information Modeling (BIM) and project management tools makes it easier to figure out how much you need to order. This helps builders to plan better and get only what they need. Working as a team with architects, engineers, and suppliers so everyone knows what is needed for the job also helps get the right amount at the right time.

Using green building methods, like using recycled materials and trying prefabrication, can also help lower waste from construction work. In the end, taking care to order the right amount of materials does more than make the job run smoother. It also is a good way to support sustainability and lower the environmental impact from the construction industry by cutting back on waste and disposal, thereby providing significant environmental benefits.

Store materials properly

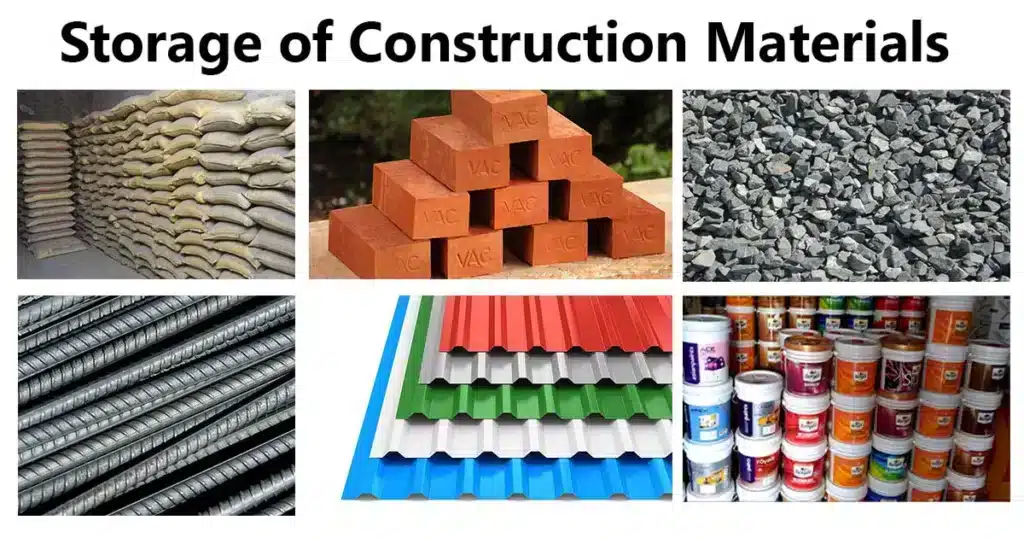

Proper storage of materials at a construction site is very important if you want to cut down on waste generation and ensure longevity. When the team stores things the right way, this helps the materials last longer, be used for their purpose, and lowers the chance that they get damaged or go bad. When you keep things in groups and use the right shelves or containers, you make it easy to find what you need. This way, there’s less risk that people will buy something again just because it was lost or misplaced.

Also, having places set aside to keep your materials helps you use space in a better way. It keeps the site less messy, makes it safer for people by lowering trips or falls, and it is just easier to get around. Storing materials inside or using covers helps to keep them safe from things like rain, sun, or heat, so the materials do not go bad. This will save both money and time, which is good for everyone. For official guidelines and standards, refer to a gov website.

If you label everything and keep track of what’s in inventory, that will help people spot what they need fast. It also avoids long waits or buying the same stuff several times. In the end, being organized makes everything work better at the construction site. You end up with less waste, better safety, and you help with sustainability, because things last longer and good materials do not end up in the trash.

Work closely with suppliers

Reducing waste on a construction site takes planning and teamwork—especially with suppliers. Choosing partners who follow sustainable practices and involving them early helps cut waste, improve recycling, and use materials more efficiently.

Good communication keeps everyone focused on waste reduction. It also opens the door to new ideas like lean construction, better packaging, and choosing recyclable materials. Regular check-ins and feedback help improve these efforts over time.

Working closely with suppliers makes it easier to order the right materials, store them properly, and prepare them for reuse. These steps, supported by EPA guidance, reduce waste, improve efficiency, and save money.

At Bargain Dumpster, we’re ready to support your project. We’ll help you choose the right number and size of roll-off containers and keep your job site running smoothly—no matter the size.

Educate Your Team

Teaching your team about sustainable waste management practices is a key part of reducing waste at a construction site. When you help team members see the environmental impact of their actions, they can play an active part in waste management. Training sessions focusing on recycling, sorting waste the right way, and reusing things will give workers the knowledge they need to make smart choices. Also, building a mindset of sustainability in the group helps people feel open about sharing ideas and trying new ways that help with waste reduction. Holding regular workshops and hands-on activities keeps everyone involved and makes sure each person knows what to do to cut down construction site waste.

Promoting sustainable practices can help lower the carbon footprint of construction projects. It also helps the team feel more responsible about what they do on the construction site. By showing the importance of source reduction, like making better use of materials and cutting down on too much packaging, people can help the worksite run better. When everyone talks together about waste management and ways to reduce waste, it helps the team feel part of the solution. This makes them want to help with reaching all the sustainability goals. Teaching your team about waste reduction is the first step to success in managing waste. It makes sure that everyone is doing their part to care for the environment at the construction site.

Encourage Sustainable Practices

Supporting sustainable practices on construction sites is a good way to lower waste and help the environment. A focus on sustainability starts when people see how what they do can affect the earth. Teams can cut down on their carbon footprint when they put sustainable practices first, and this can also help the whole project run better. Simple changes, like using refillable water bottles instead of single-use plastic, can do a lot to lower the carbon footprint. Also, using digital files instead of paper can help people talk to each other more easily and create less waste.

Also, when you build a culture that rewards people for making eco-friendly choices, it helps more people join in. If you recognize team members who take part in recycling or come up with new ways for waste reduction, others may want to join them. When everyone in construction projects—including suppliers and subcontractors—works together, waste management can improve. Teams that work as one can spot what needs to get better and make real changes to meet sustainability goals. When you put sustainability in the center of daily work on construction projects, you can make real progress in waste reduction and help protect the environment for the future.

Monitor and Analyze Waste Generation

Keeping track of construction waste on a site is very important for good waste management. When you watch the amount of waste and look at the different types of materials and numbers of materials being thrown away, construction teams can learn more about their own waste. This can help people see where things could be better. They can work on ways to cut back waste. When you know what types of construction waste are on your site—like too much concrete or lots of packaging—you can change how you order things. This helps you use materials in a better way and leads to less waste over time. Good waste management helps you get the most out of the materials and do less harm to the environment.

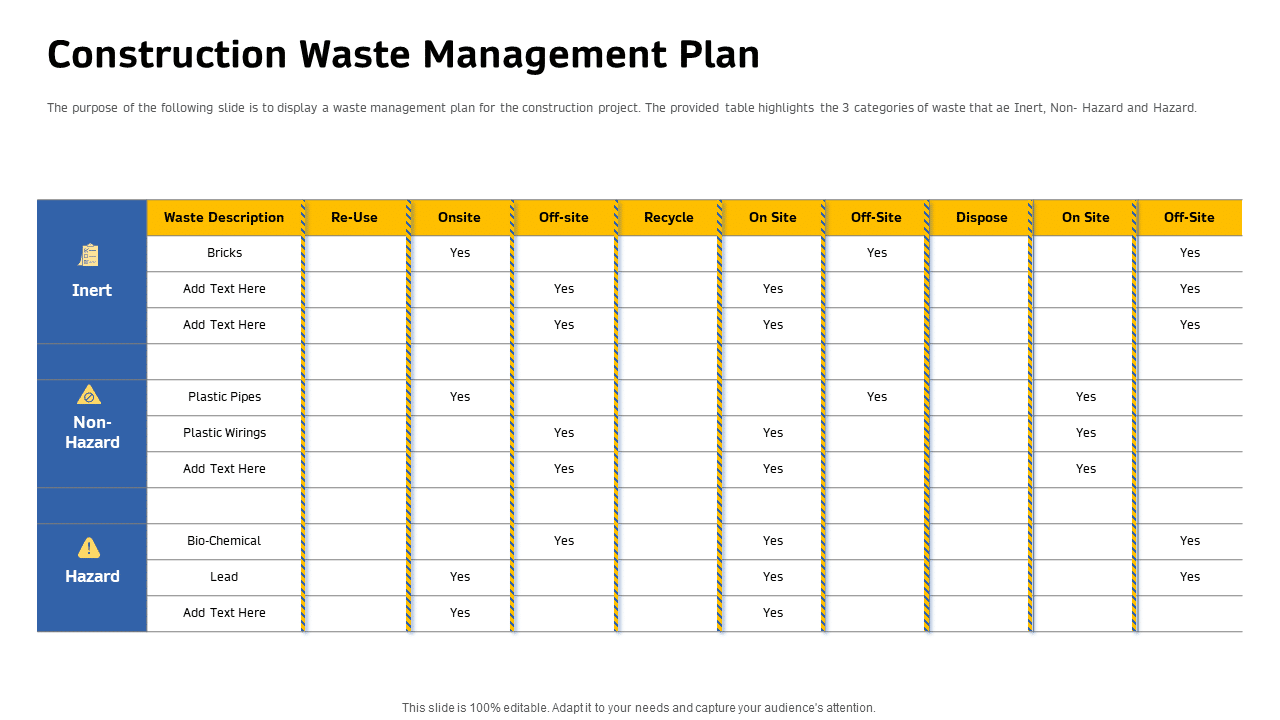

To make this monitoring easier, you can create a waste generation table. This table helps by sorting out different types of waste. For example, you can sort into recyclable materials, hazardous waste, and general debris. The table lets you keep track of how much waste you have from each type over time. A waste generation table might look like this:

By checking this data often, construction teams can see what is working and what needs to change. They can work to recycle more and lower the amount of waste generation. When they share this information with others who are part of the project, it helps everyone feel responsible. This way, people work together for better and more sustainable construction. With careful tracking and looking at the results, the construction industry can move forward in waste management and take better care of the environment. This can lead to more effective waste management and show that the industry is thinking about what is good for the planet.

What are the most effective tips to reduce construction site waste?

To effectively reduce construction site waste, prioritize recycling materials, implement a waste management plan, and conduct regular audits. Additionally, choose sustainable materials and train workers on waste reduction practices. Engaging all team members in these efforts fosters a culture of sustainability and significantly minimizes environmental impact.