Containing Dust From Power Tools (And Disposing of Debris)

Containing dust from power tools is not about creating a spotless workshop. For DIYers and home hobbyists, it’s essential for reducing risk, protecting your lungs, extending the life of your tools and making the shop a more pleasant place to be. You don’t necessarily need an expensive removal system to make a meaningful improvement. With a thoughtful approach, even a small garage or basement shop can manage dust effectively.

Why Wood Dust Is More Than Just a Mess

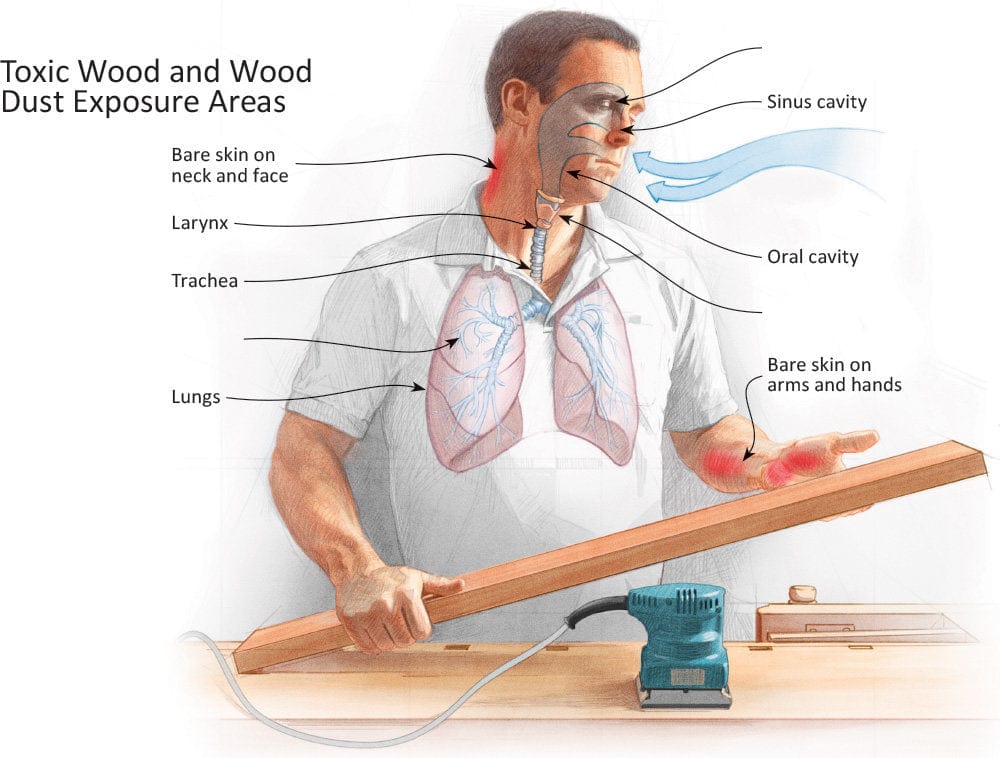

DIY projects, woodworking and other power-tool-based hobbies are deeply satisfying but indisputably messy. When power tools cut, shape or sand wood, they create particles of various sizes. Larger chips fall quickly to the floor and are mostly a housekeeping issue, but fine particles are a different matter. They can stay airborne for hours and carry well-documented health hazards if they enter your lungs.

Short-term exposure to wood dust can:

- Irritate the eyes, nose and throat

- Cause coughing or sneezing

- Worsen asthma or other respiratory conditions

- Result in skin irritation or allergic reactions in sensitive individuals

Long-term exposure is more concerning and strongly linked to nasal cancer and other sinus concerns. Multiple health agencies have classified wood dust as a known human carcinogen. Repeated exposure over the years increases the risk, even at levels commonly found in small workshops. Certain species of wood, such as Western Red Cedar, are known to be more toxic than others, so dust control is important regardless of how you work, how often or what materials you use.

Fine airborne wood dust is also combustible. While explosions are rare in home shops, an accumulation of combustible materials combined with a spark or static discharge can ignite fires. It also shortens the lifespan of your tools by infiltrating motor housings, bearings and switches, leading to overheating and premature failure.

Finally, dust migrates into living spaces, coats stored items and can affect the air quality of your entire home. In short, managing it is not optional housekeeping. It is a core part of responsible and safe DIY or woodworking.

A Guide to Dust Collection for the Home Workshop

Dust collection works best when approached as a tiered system. Instead of searching for a single, perfect solution, think in terms of levels that match your current needs, space and budget. Many hobbyists start small and upgrade over time.

Level 1: The Shop Vacuum

For many DIYers, this is the first step, and for good reason. Shop vacs are affordable, widely available and extremely versatile, as you can use them for general cleanup and liquid spills. Their strong suction makes them effective for handheld tools with small dust ports.

However, shop vacs move relatively low volumes of air compared to dedicated dust collectors. Filters clog quickly, which reduces airflow and performance. Many standard filters also allow the finest dust to pass through.

To maximize a shop vacuum’s effectiveness:

- Use high-efficiency filter bags designed for fine particles.

- Upgrade to a HEPA-rated filter if available for your vacuum model.

- Add a cyclone separator — often called a “dust deputy” — in front of the vacuum. This device spins incoming air, allowing heavier particles and chips to drop into a separate container, thereby reducing filter clogging.

With these upgrades, a shop vacuum becomes a surprisingly capable collection solution for small tools and light-duty work.

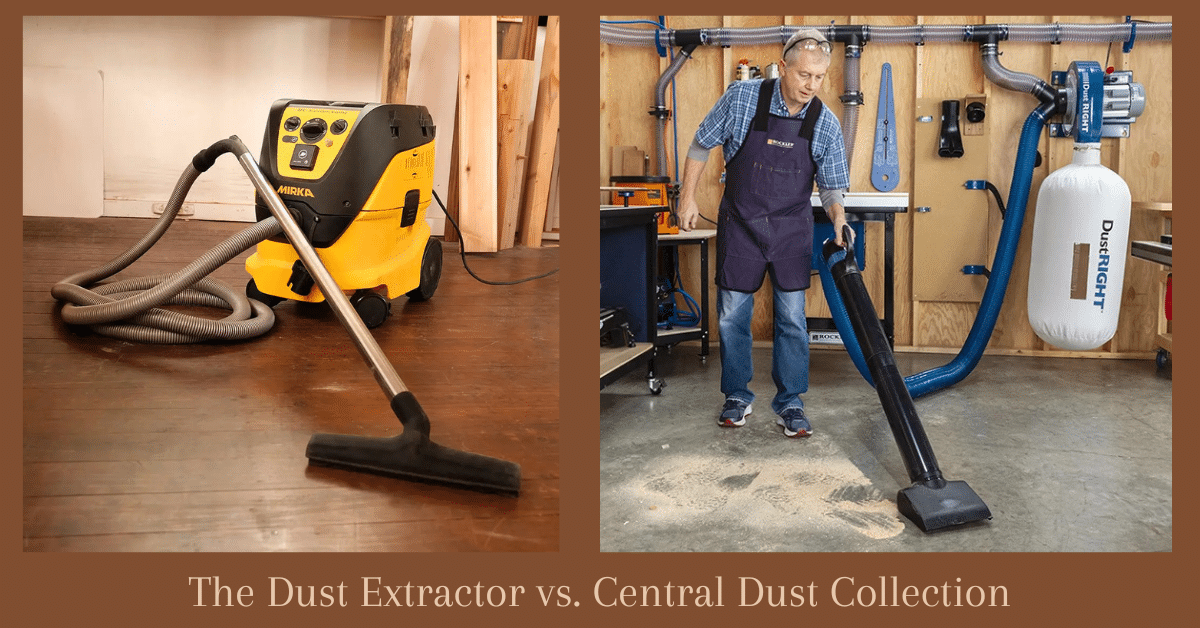

Level 2: The Dust Extractor

These machines resemble shop vacuums, but are designed specifically for controlling fine dust. They typically have higher sustained airflow, better filtration and features tailored to workshop use. Many models feature true HEPA filters that are capable of removing extremely fine particles. Automatic tool activation is another common feature, enabling the extractor to turn on and off in conjunction with the connected tool.

For home shops, dust extractors are particularly effective when paired with sanders, routers and track saws. They excel at capturing debris directly at the source before it becomes airborne. While more expensive than shop vacs, they offer a noticeable improvement in air quality and are often quieter, which is a meaningful benefit in residential settings. For serious hobbyists, a dust extractor often represents the sweet spot between affordability and performance.

Level 3: Central Dust Collectors

Central dust collectors are for larger, more permanent workshop setups. They move large volumes of air at relatively low pressure, making them ideal for tools that produce heavy chips rather than just fine dust.

Single-stage collectors pull material directly into a bag or canister, while two-stage systems separate chips before air reaches the filter. They are commonly connected to tools like planers, jointers and table saws via fixed ductwork or flexible hoses.

For a home workshop, central dust collectors make sense if you have multiple stationary tools and enough space to dedicate to a permanent installation. They are more expensive and require planning, but they significantly reduce cleanup time and help keep floors and work surfaces clear of debris.

Which Power Tools Create the Most Dust?

Not all tools are equal. Some create relatively manageable chips rather than clouds of fine particles. Understanding the types of tools thast create the worst hazards helps you prioritize where to focus your dust collection efforts.

The biggest offenders in home workshops include:

- Miter saws and table saws: High-speed cutting tools spin blades at high revolutions per minute (RPMs), ejecting debris with significant force. Table saws produce a mix of chips and fine dust, while miter saws can spray dust in wide arcs unless well-enclosed.

- Routers: These high-RPM shaping machines remove material aggressively, resulting in large volumes of fine dust that is often thrown in unpredictable directions, especially when edge routing.

- Sanders: These are the primary source of the most dangerous dust — ultrafine particles. Whether orbital, random-orbit or detail sanders, these tools are designed to turn solid material into powder.

If you are doing occasional DIY jobs, like sanding your kitchen cabinets to smooth scratches before repainting, you can usually get away with a quick cleanup using your home vacuum cleaner. However, for more regular home improvement enthusiasts or hobbyists, focusing on these tools first will deliver the biggest improvement in air quality and cleanliness.

Smart Tool Selection as Your First Line of Defenss

Choosing tools designed with dust management in mind can dramatically reduce the amount that escapes snto your shop. When evaluating tools, pay attention not just to power and accuracy, but also to how well they manage debris.

Consider quality dust ports, which are well-designed, positioned close to the action and sized appropriately for common hoses. Integrated dust shrouds are another great option. These surround the blade or bit, helping direct waste into the port rather than allowing it to spray outward.

Some sanders are explicitly designed to mitigate dust at the source for added safety. Self-generating vacuum sanders actively pull material away from the work surface, thereby reducing dust. This improved visibility also increases accuracy, making it a big plus for complex sanding jobs. sChoosing tools with better dust control doesn’t eliminate the need for collection equipment, but it does reduce the workload on your system and improve overall results.

How to Dispose of Wood Debris Safely

Capturing dust is only the first part of the process. Proper disposal is the final part of the puzzle and one that is often overlooked.

Collected material should be handled carefully to prevent it from becoming airborne again. Fine dust in particular can easily escape during disposal if handled roughly.

Seal it in heavy-duty plastic bags. Avoid shaking or dumping loose particles into trash cans, as this releases them back into the air. Some municipalities permit clean, untreated wood waste to be included in regular household trash. Others may have restrictions, especially for dust from treated wood or composite materials.

Piles of sawdust and shavings are a fire hazard. Do not allow it to accumulate in corners, near heaters or around electrical equipment. Empty collection containers regularly and store bags away from ignition sources.

Recycling Sawdust

Disposal isn’t the only option for regular sawdust. If you are a keen gardener, you can compost it or use it as mulch. However, fresh sawdust leaches nitrogen from the soil, so if you use it as a mulch, you will need to supplement with nitrogen. You can use aged or composted material instead. To compost it, mix it well with food scraps or grass clippings.

Clean sawdust from untreated wood can be used as animal bedding for chickens, rabbits, guinea pigs or other small animals. Double-check first that the type of wood you used is not toxic to animals.

You can also mix sawdust with wax and lint to make fire starter bricks, or spread it on icy paths during the winter to help avoid slips.

Frequently Asked Questions About Workshop Dust

Even with a good system in place, certain questions often arise. Here are answers to a couple of the most common ones about managing workshop dust.

1. What Should I Do About the Fine Dust That Escapes My Collection System?

Consider adding an ambient air filtration unit to your space. A budget-friendly option is to strap a high-quality furnace filter to a standard box fan, which will circulate and clean the air by capturing the particles that some collection systems miss.

2. Can I Just Use My Household Vacuum?

Other than for very occasional use, using a household vacuum is not advisable. Filters will quickly clog, and this can burn out the motor. Shop vacuums are specifically designed with more robust motors and filtration systems to handle this type of job safely and effectively.

Creating a Cleaner, Safer DIY Workspace

The most effective approach to containing dust from power tools combines multiple strategies. Choose tools with good material management, capture the waste at source with appropriate equipment, clean your shop regularly and dispose of the debris safely. With those guidelines in mind, you can enjoy your hobby or your DIY projects safely, while protecting your health and your home.